Introduction to Chain Drives

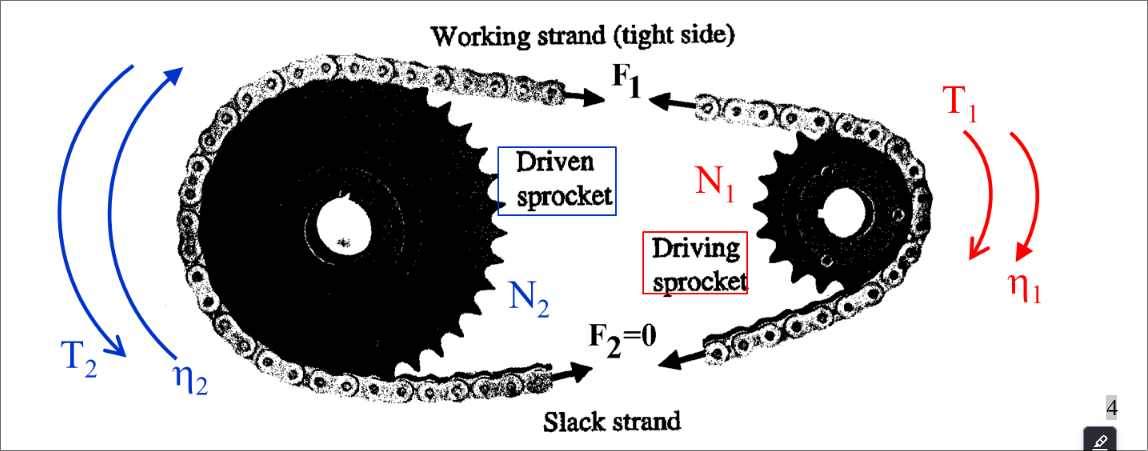

One side of the strand is always slack with zero tension and power is transmitted solely by the tight side tension, which explains why chain drives generate a smaller shaft load than belt drives.

Thus chain drives:

- require smaller, less costly bearings and shaft

- more compact, powerful and efficient than belt drives

Application of Chain Drives

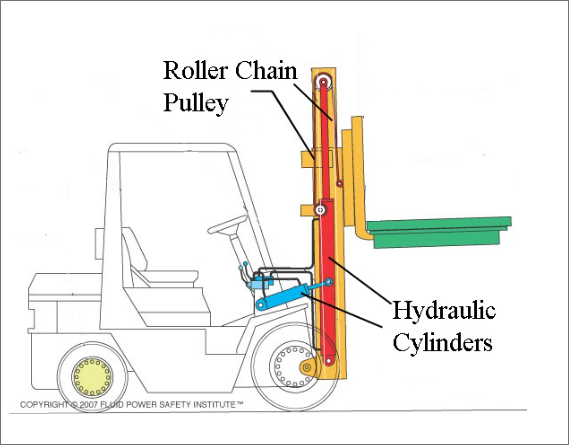

- Raising and lowering loads on a forklift

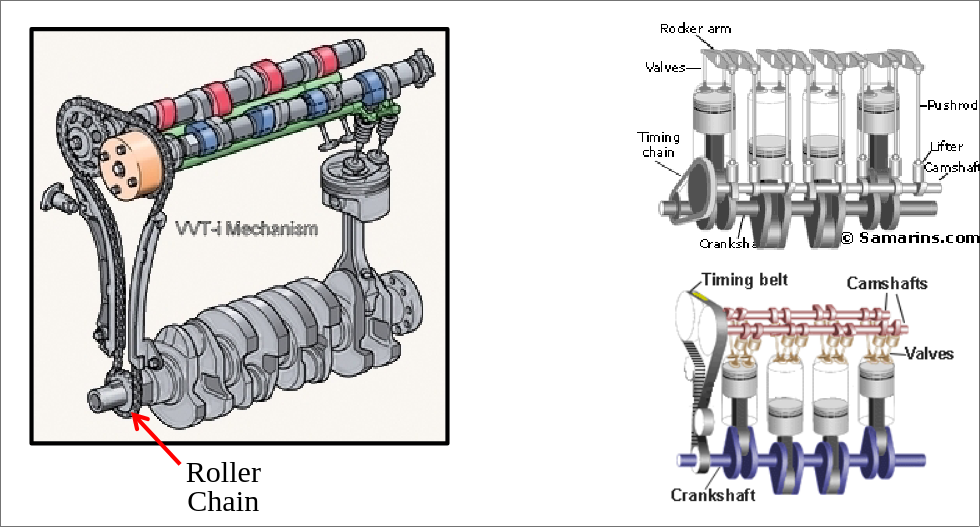

- For synchronizing movement in for valve timing in engines

- Using a chain over a belt boasts better durability and thus less need for repairs

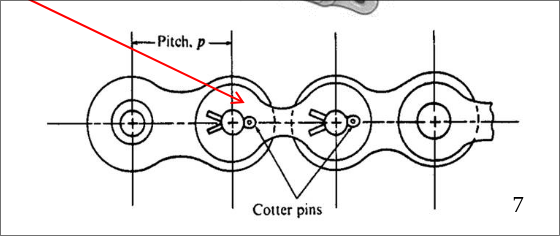

Introduction to Roller Chains

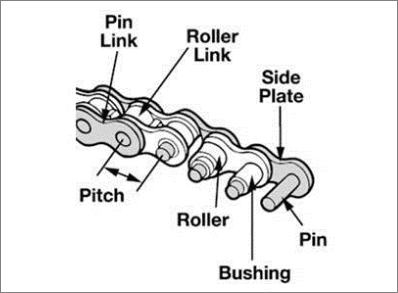

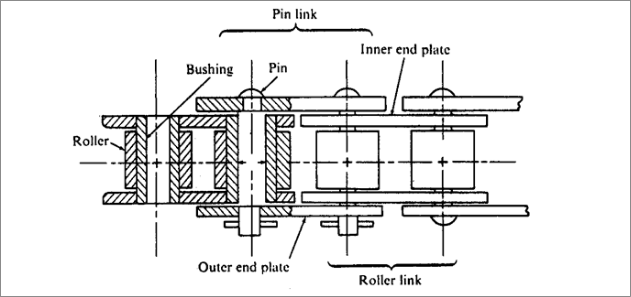

Roller chain is the most widely used type in which the roller on each pin provides exceptionally low friction between the chain and the sprockets.

- Chains are endless → advantage over v-belts and gears

- Links are detachable to easily remove the chain

- A roller chain is generally made of hardened steel and sprockets of steel or cast iron.

- Roller chains have a high efficiency of 97 to 99% and can be used for heavy loads at speeds up to 20 m/s.

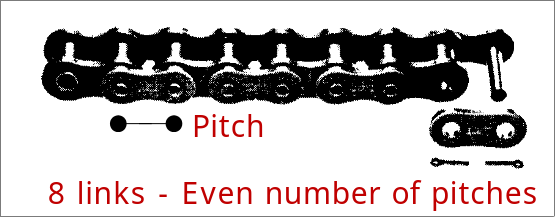

Even and Odd number of links/pitches

Since each roller link requires a pin link for assembly, a chain normally has an even number of links

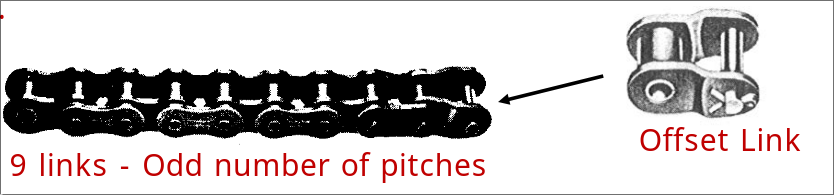

If an odd number of links is required, it is necessary to use an offset link.

- Offset links wear faster than straight links and should be avoided whenever necessary.

Roller Chain Classification

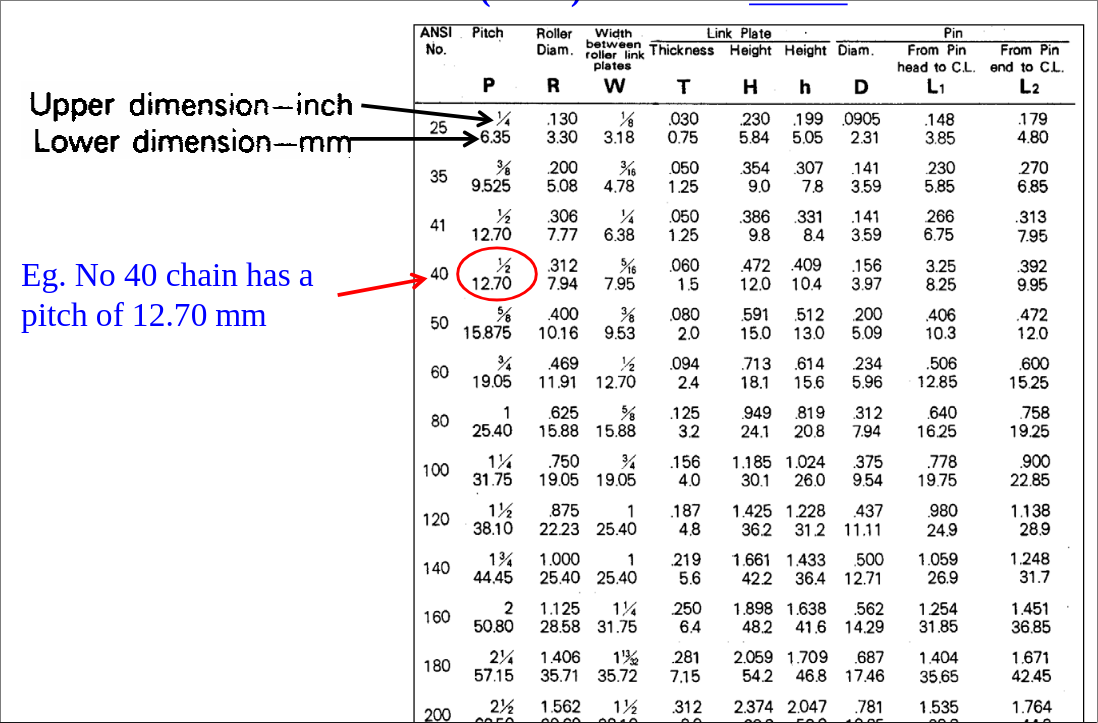

All chains are classified according to the pitch.

- The dimensions of standard sizes for a single strand chain specified by American National Standards Institute (ANSI) is shown in Table 1.

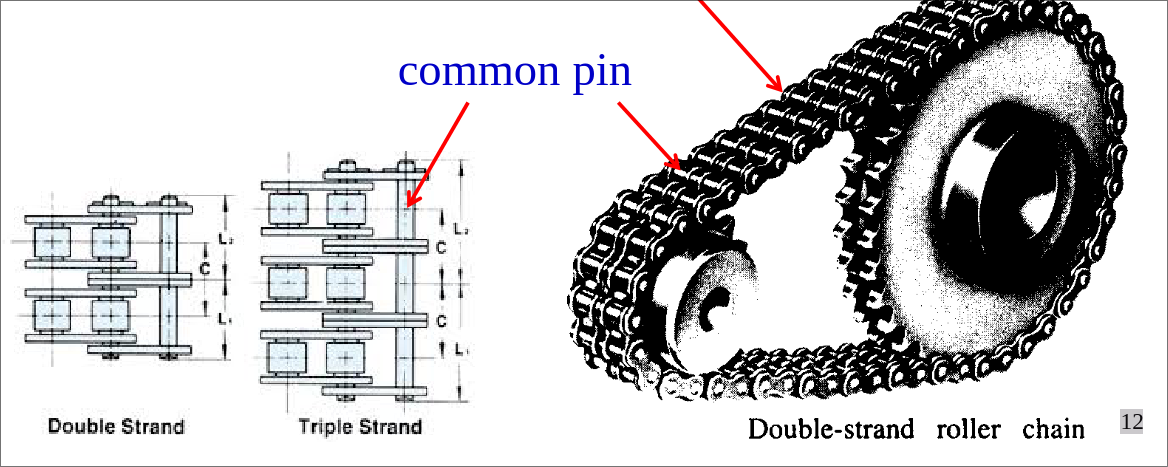

Multi-Strand Roller Chains

Multi-strand such as double-, triple- and quadruple-strand roller chain and sprockets are also stocked in most standard sizes according to size by the American National Standards Institute (ANSI).

Failure modes of Roller Chains

Roller chains seldom fail because they lack tensile strength; they more often fail because they have been subjected to a great many hours of service

- Actual failure may be due either to wear of rollers on the pins or fatigue of the surfaces of the rollers.

Power capacity of Roller Chain system

At lower speed → determined by fatigue life of link plates

At higher speed → determined by roller bushing fatigue life

At VERY high speeds → determined by galling or a phenomenon of localized cold weld on the bearing surface between a roller and its bushing that resulted in surface roughening as the weld is broken.