Limits and Fits

Limits terminology

- Basic size = Theoretical size — e.g. 48.00

- MMC for shaft/hole — Nicest value / least d.p

- Tolerance notation — 48.00 ± 0.02

- Tolerance = difference between limits of size — e.g. 0.04

- Limits of size = Largest and Smallest size permitted — 48.02 (largest) 47.98 (smallest)

- Actual size = measured size

- Maximum material condition (MMC) — limit of size resulting in maximum material involved

- Minimum material consition (LMC) — limit of size resulting in minimum material involved

Fits terminology

- Clearance fit — worst case scenario will still have clearance — size range do not overlap

- Interference fit — all cases have interference — size range always overlap

- Transition fit — cases can either have clearance or interference — partial overlap of size range

- Upper deviation =

- Lower deviation =

- Fundamental deviation — deviation closest to basic size

- Allowance =

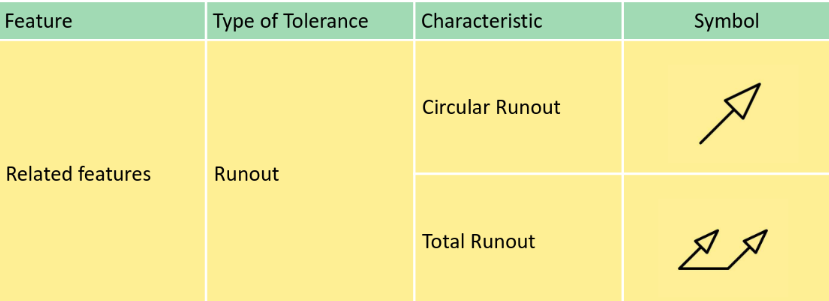

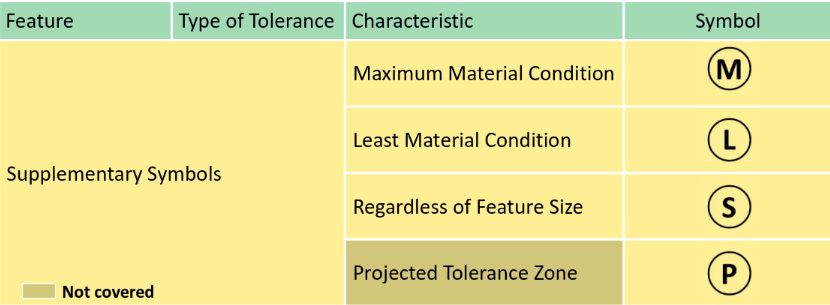

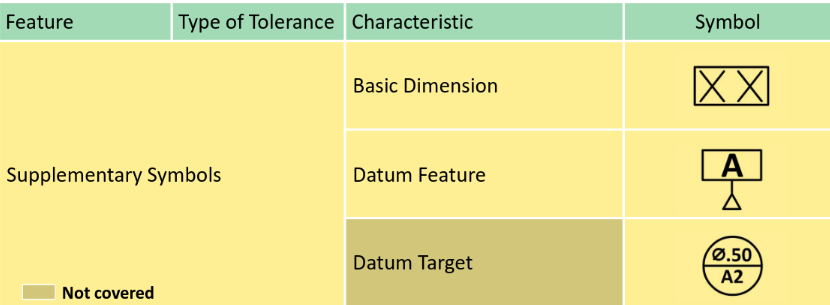

GD&T Fundamental

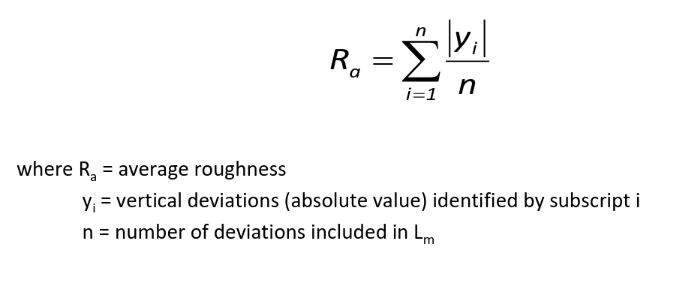

Surface texture

Notations

-

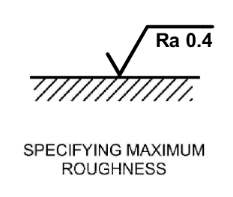

Specifying max roughness

-

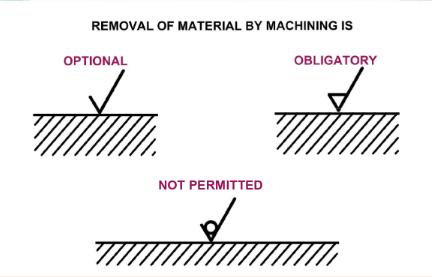

Removal of material instructions

-

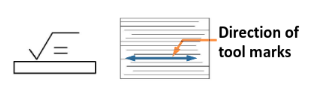

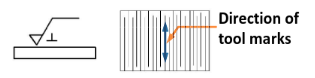

Lay symbol =

-

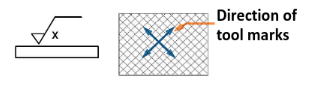

Lay symbol X (honing)

-

Lay symbol C (turning)

-

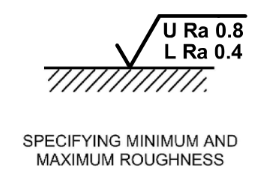

Specifying max & min roughness

-

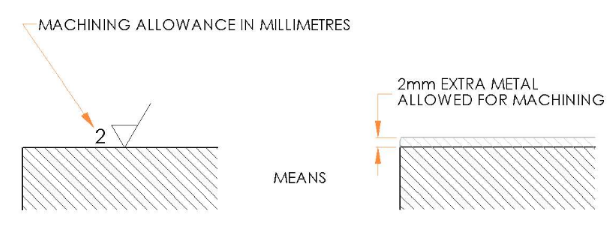

Machining allowance

-

Lay symbol (grinding / shaping)

-

Lay symbol M (lapping)

-

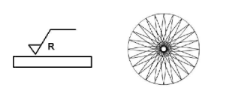

Lay symbol R

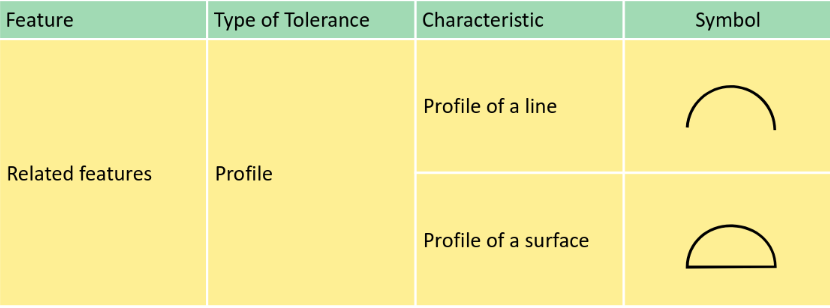

Tolerances

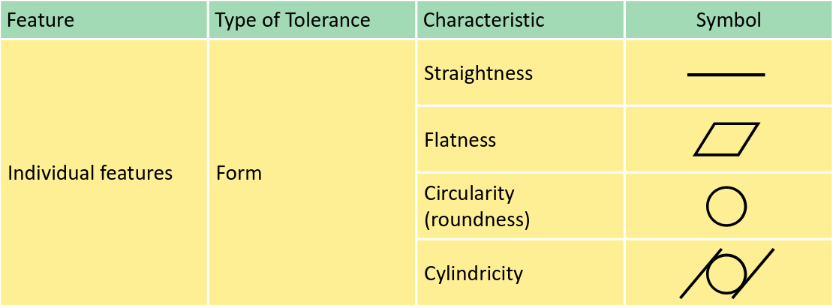

Form tolerances

Straightness

For parallel line element on surface, its allowed to vary in depth within straightness tolerance

- Flatness: Same as straightness but for surface Virtual condition (VC) VC = MMC (Shaft) + Geometric tolerance

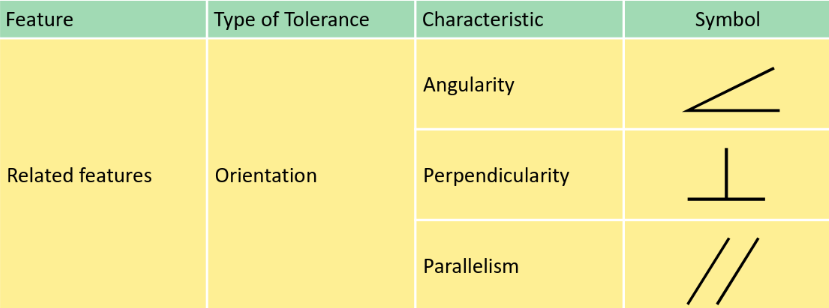

- The modifier allows the feature surface(s) to exceed the maximum material boundary by the amount of form tolerance, meaning that VC = MMC + tolerance. Angularity

Deviation of the angle of a feature — e.g. center line of hole

- Parallelism and Perpendicularity is similar

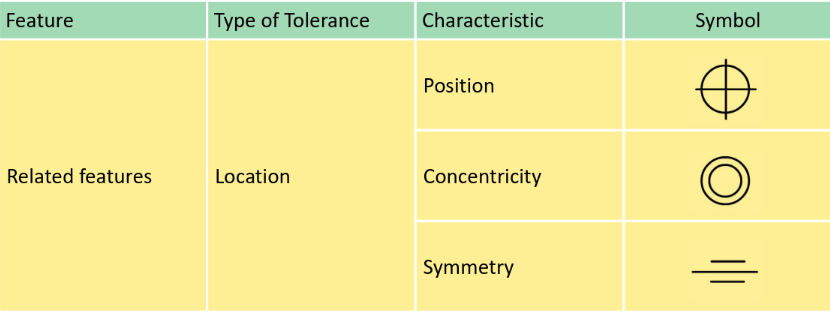

Location tolerance

Position